Type: edible oil refining

Capacity: 10-600T/D

Material: soybean oil, rapeseed oil, peanut oil, cottonseed oil, sunflower oil, palm oil

Major equipment: degumming tank, centrifuge, heat conducting oil boiler, decolorization tower, deodorization tower

Application: intermittent, continuous edible oil refining process for multiple oil seed refining

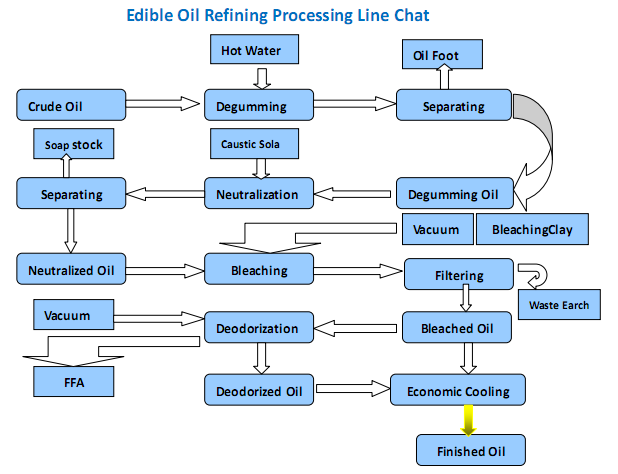

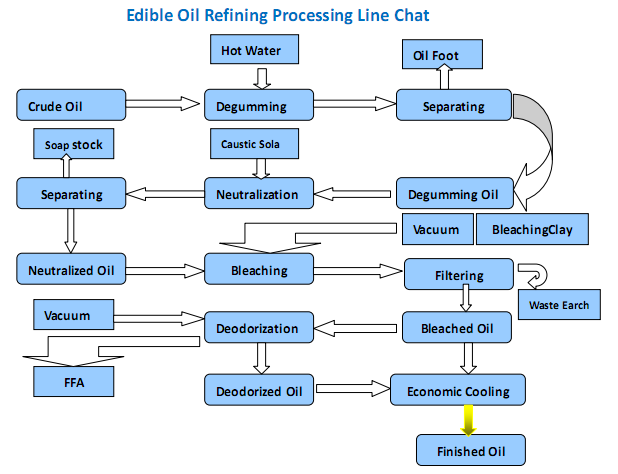

Edible oil refining machine provides professional oil refining process of degumming, dehydration, deacidification, decolorization, bleaching, deodorization, and dewaxing. The complete set of oil refinery machinery adopts the most advanced physical refining or chemical refining technology on basis of oil property to get the purest edible oil with the lowest cost consumption.

General introduction of Edible oil refining process line:

● Advanced designed edible oil refining process.

General introduction of Edible oil refining process line:

● Advanced designed edible oil refining process. QI’E designs advanced and professional edible oil refinery process to obtain high purity refined oil. It contains hydrated degumming, alkali refining deacidification, negative pressure decoloring process through blenching earth, deodorizing to remove odor components in oil, and dewaxing to remove wax in oil.

The heat conduction oil boiler can supply above 280°C energy to each device, steam generator can supply steam for deodorizing and distillation, vacuum pump can supply vacuum for dehydrate, decolor and deordor. The press filter is used to filter clay and filter out clear oil, and air compressor to blow dry blenched clay and empty the leftover oil in press filter.

● Automatic control system assures high efficiency edible oil refinery. The application of advanced automatic control system in large edible oil refining plant provides the most secured, reliable production in entire workshop and monitors the operation status by controlling the computer terminals.

● Low production cost and high purity refined edible oil. QI’E adopts compact edible oil refining process to obtain high purity refined edible oil with impurity less than 0.2%. The adoption of waste recycle system can protect environment efficiently.

FAQ:

1. Why do the edible oil need be refined?

Ans. No matter pressing oil or solvent extracted oil, they need to be refined before eating. as a result of there are several impurities within the crude edible oil, the oil is not good for human health. The impurities like water, FFA, resin, etc. can create the oil go unhealthy before long. once refining, the oil is good for health and easy to storage for long time.

2. How to start an edible oil refining plant?

Ans. Edible Oil refining plant have to be a large oil operation. Anyone wanting to start a local edible Oil refining plant could do so with a refining. There is need for large equipment, storage, utilities, auxiliaries and land. One can even start with an existing structure by converting it to a refining plant.

3. How many edible oil refining method?

Ans. Edible oil refining the process is consists of two method i.e. Chemical Refining and Physical Refining.

4. What is the Chemical Refining process?

Ans. Oil and Fats with low FFA and contain three basic step i.e. Neutralizing, Bleaching and Deodorizing.

5. What is the Physical Refining process?

Ans. Oils and Fats with high FFA and contains three basic steps i.e. gum conditioning, Bleaching, Stripping and Deodorization.

Our Service

1 the shipment : we will be responsible for the shipment details and arrange related thing for customers according to their requirements .

2 the production: after we receive the deposit from the customers , we will arrange the production . And we can make delivery within 10 days after receiving the deposit .

3 the matched equipment . For some special raw materials , like copra , we will also provide the copra crusher , and roaster . For palm kernel , we can also provide you the palm kernel crusher and roaster . In this case , the oil out put will be much higher than common directly extraction .

4 the exporting experience . We have been in this field for many years . We can help customers solve all related questions about the exporting procedure .

5 the operation instruction . when our customers get our machine , we can also teach the customers the operation procedure . We will make the customers know the machinery operation in the short time .

6 the installation.We provide engineers after your receipt of equipments for on site installation, debugging and training.

![[!--oldtitle--] [!--oldtitle--]](/uploadfile/image/201610/201610151350391394.png)